Engineering Growth and Delivering Lasting Solutions

Since 2019, DMS has grown exponentially. The company has expanded into new sectors and evolved into an independent company known for delivering lasting solutions to complex problems.

Deliver excellence, inspire innovation, and provide sustainable solutions.

We provide services that meet the highest standards, emphasizing reliability, attention to detail, and customer satisfaction. We exceed expectations in both quality and performance.

We have a can-do attitude and are committed to innovation and turning ideas into reality no matter how difficult. With persistence, we make the impossible possible.

We place great importance on building strong partnerships to achieve shared goals. We drive growth and prosperity with our clients by providing exceptional service and collaboration.

The Origins of Dexon Mechanical Solutions (DMS): From Support Team to Industry Pillar

Dexon Mechanical Solutions (DMS) started out small. In 2019, Dexon Technology opened the department to support Dexon’s core work in-line inspection (ILI) of oil & gas pipelines. DMS' job was to deal with the odds and ends of ILI work, such as pipeline cleaning, infrastructure modifications, and running to the local hardware store (sometimes a hundred kilometers away) to get PVC pipe. The crew was part glorified errand-runner and versatile problem-solver.

DMS’ transformation from a support team to a stand-alone company began in 2020. Dexon Technology assigned the team to build an infinity loop test facility. This facility is a specialized test yard designed for ILI tool development and testing. It is composed of pipelines interconnected pipelines that allow tools to run continuously for as long as necessary. Often, tools will run for 72 hours straight and over a hundred kilometers during test runs. The yard provides a controlled environment that allows Dexon’s engineers to test and refine their tools under real-world conditions.

DMS delivered. The test yard was completed on time and to specification. Pumps. Pipelines of various dimensions. Underground pipes for water run-off. Turns of multiple degrees. All this was built to make testing Dexon Technology’s tools as pain-free and accurate as possible. The yard proved a success, and the fact that it is still being used five years later with little modification is a testament to the designers’ skill.

This project’s success proved that DMS had the expertise to take on more ambitious challenges. Seeing the potential of the team, DMS became a subsidiary of Dexon Technology in 2021.

The newly founded company worked directly with clients beyond its parent company to bring engineering know-how to local businesses. In the early days, much of DMS' work was inglorious but important. The fledgling company conducted hydrostatic tests of tools a skill mastered through the company’s collaboration with Dexon’s ILI teams.

DMS quickly moved beyond routine testing. In 2022, the team built a 12-inch ILI test facility designed for a tool that detects mercury levels in pipelines. Engineers installed a unique “Minion Eye” observation system a glass viewing window in the pipeline that allows operators to see the pig in action. Since ILI tools operate within pipelines, this critical information is often off-limits to engineers. The Minion Eyes corrected that, allowing designers to better understand how the tool operates and improve on existing designs. The project reinforced DMS’ ability to design and execute custom-engineered solutions for pipeline operators.

The company’s capabilities expanded in 2023 when DMS took on its most ambitious project yet a large infinity test loop. The loop was located at the facility of an innovation center for a global energy company. The test loop, designed from the ground up, replicated real-world pipeline conditions. As with Dexon’s yard, it allowed R&D teams to test new tools under a variety of conditions, from different pressure levels to temperatures.

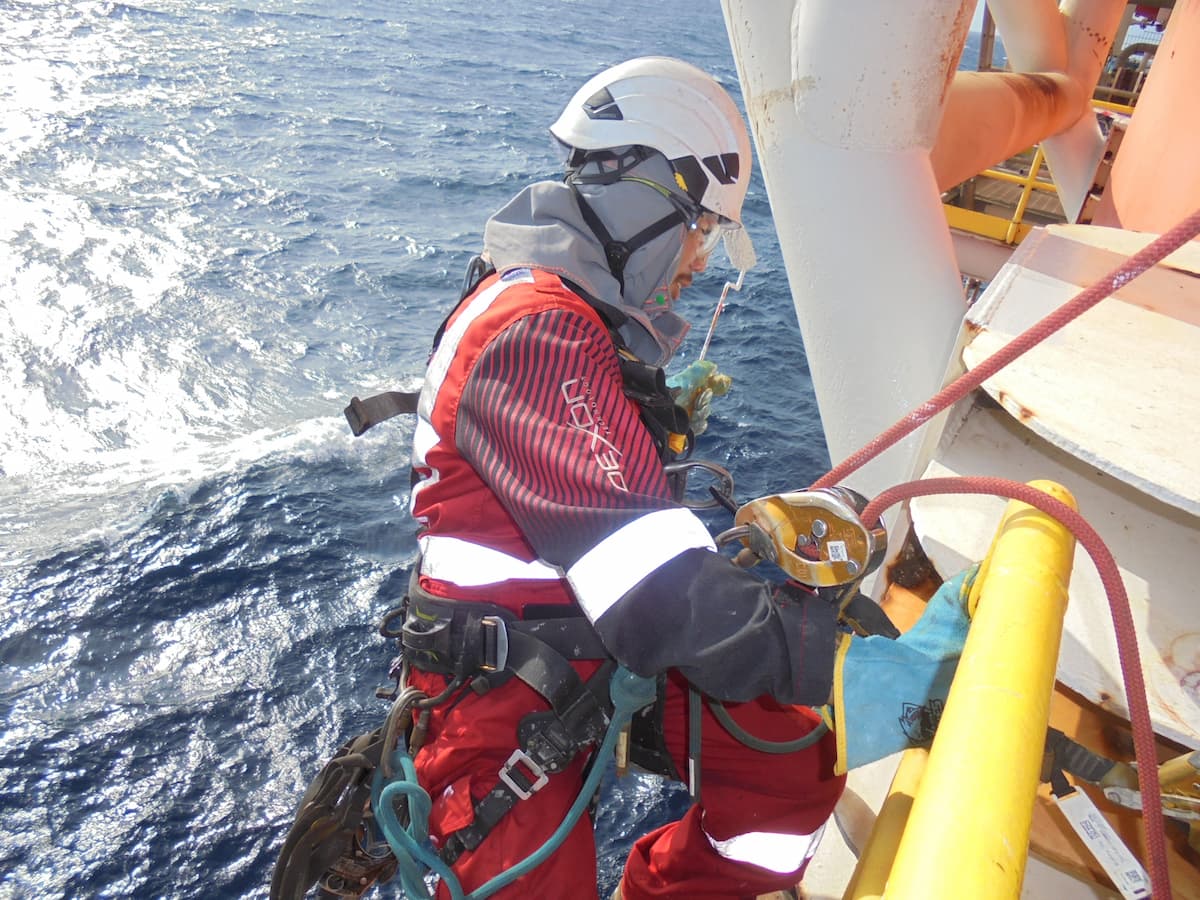

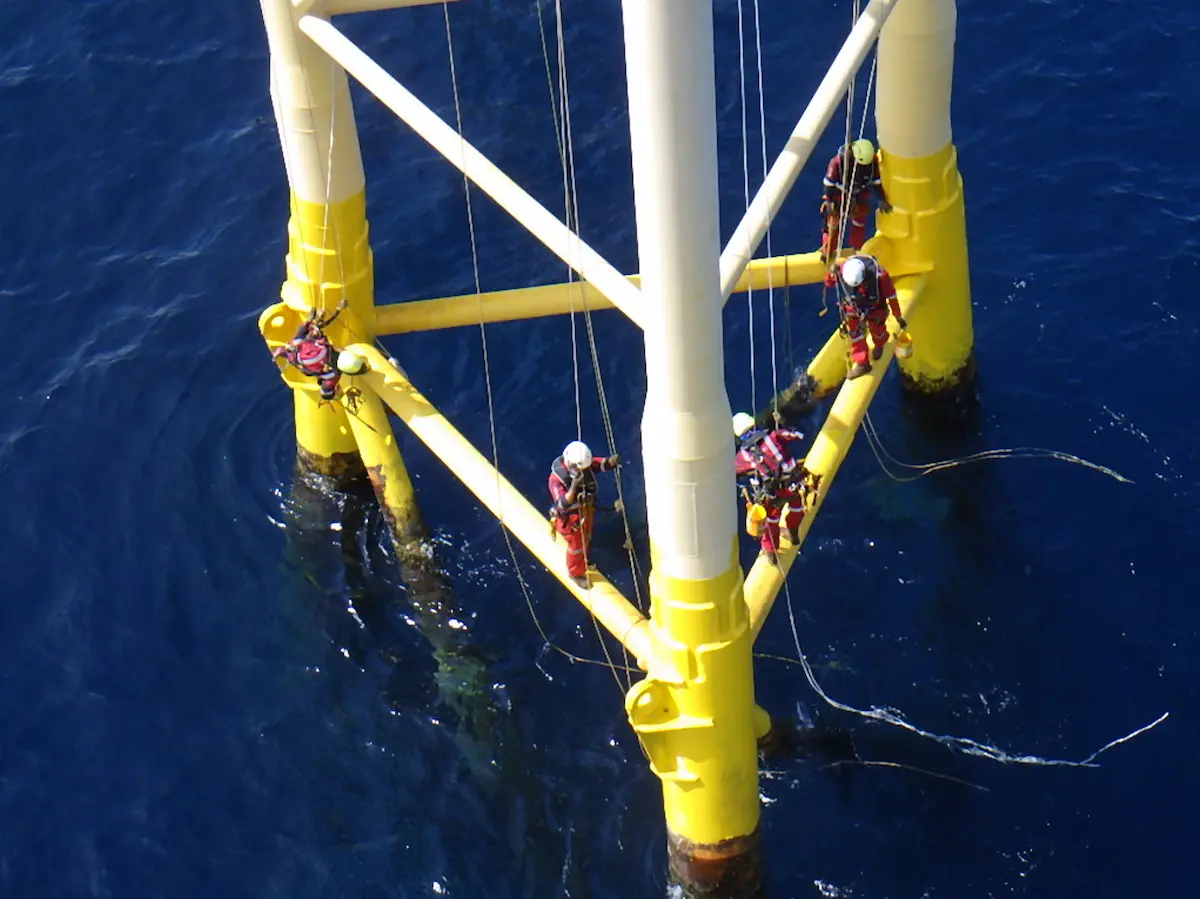

That same year, DMS secured its first major offshore job. The company won a contract from a top upstream oil & gas company to inspect and repair offshore assets marking its entry into the high-stakes world of offshore engineering.

In 2024, DMS reached another milestone. The mechanical solutions company completed a massive pipeline expansion project for one of the world’s top five energy companies. The project involved adding 18 new lines to an oil production plant. Each line had to be added during the short 1-2 hour window between production rounds.

The complex task required a range of skills. Civil engineers were necessary to install underground pipelines for temperature control. Mechanical engineers had to develop pipes that integrated with the existing system, and the design team innovated to design quick opening closures, allowing inspectors easy access to the pipes. DMS’ engineers completed the job in 12 days over three months.

Another major accomplishment in 2024 was DMS’ offshore repair work. A large, international energy company enlisted the company to fix a flare system located in the splash zone an environment notorious for extreme conditions and heavy wear-and-tear. Engineers battled high winds, heavy rains, and a tight deadline. Despite the challenges, DMS completed the repairs on time and cinched its reputation as a company that could deliver under pressure.

Looking ahead, DMS is set for even more ambitious projects. In partnership with several global engineering companies, DMS will offer next-generation subsea and topside solutions. These projects will cement its position as a leading mechanical services provider for the energy industry. With a track record of tackling challenging, high-risk projects, DMS is ready to take on whatever challenges the future holds and make the impossible possible.